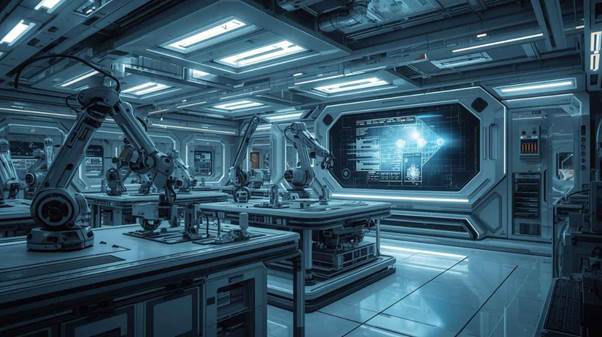

In today’s era of automation and smart technology, Robotic Vision Systems are transforming how machines perceive and interact with their surroundings. By combining advanced imaging, artificial intelligence, and deep learning, these systems enable robots to analyze, recognize, and respond with human-like precision. From manufacturing and healthcare to autonomous vehicles, this innovation is driving remarkable progress across industries.

In this article, we’ll explore how visual sensing, object recognition, and intelligent automation are shaping the next generation of machine intelligence setting the stage for a future where robots not only see but also understand the world around them.

Understanding Robotic Vision Systems

What Are Robotic Vision Systems?

Robotic Vision Systems integrate advanced sensors, imaging devices, and smart algorithms that enable machines to capture and understand visual information.These systems enable robots to identify objects, measure distances, and make decisions based on the visual information they collect. Acting as the eyes of automation, they bridge the gap between mechanical precision and cognitive understanding.

Unlike traditional automation tools that rely on pre-programmed movements, modern vision-enabled robots adapt to changing environments. This adaptability makes them vital in areas like manufacturing, logistics, medical robotics, and autonomous vehicles. By integrating visual perception with artificial intelligence, these systems are pushing the boundaries of what machines can achieve independently.

Evolution and Background

Early Stages of Machine Vision

The roots of robotic vision trace back to the 1960s, when researchers began experimenting with computer vision. Early systems used basic cameras and simple algorithms to detect shapes and contrasts. These primitive models laid the groundwork for what would later evolve into intelligent visual systems capable of recognizing complex patterns and actions.

Integration with Artificial Intelligence

The real breakthrough occurred when machine learning and neural networks entered the scene. Artificial intelligence allowed machines not only to detect visual cues but to learn from them. Through deep learning, vision systems improved their ability to identify and classify objects with minimal human intervention.

Today’s robotic vision technology combines 3D imaging, real-time analytics, and pattern recognition providing robots with human-like sight and reasoning capabilities. This combination of hardware and intelligent software is what drives innovation in modern automation systems.

Related Article: Robotic Vision Systems: Transforming Industrial Automation Through Intelligent Perception

Importance in Modern Industries

Enhancing Efficiency and Accuracy

Robotic vision plays a central role in boosting efficiency across industries. In manufacturing, for instance, these systems enable robots to perform precision inspections and detect product defects faster than humans.

Key contributions include:

- Improved quality control through real-time inspection and detection

- Increased productivity by minimizing downtime and manual intervention

- Enhanced consistency in repetitive or delicate tasks

Applications Across Sectors

The impact of vision-based robotics extends far beyond factories.

Some notable applications include:

- Healthcare: Robotic surgery and diagnostic imaging leverage high-resolution vision for precision.

- Agriculture: Drones and smart harvesters use vision systems to monitor crop health and improve yield prediction.

- Logistics: Automated sorting and packaging rely on object detection and motion tracking.

- Automotive: Self-driving cars use multi-sensor vision to navigate and avoid obstacles safely.

These applications demonstrate how vision-driven intelligence is revolutionizing operations in both industrial and everyday settings.

Benefits of Robotic Vision Systems

Transforming Automation Capabilities

The introduction of vision technology has turned robots from rigid machines into adaptive problem-solvers. Key benefits include:

- Enhanced adaptability: Robots can handle diverse environments and unpredictable variables.

- Reduced human error: Automated inspection and navigation minimize mistakes.

- Cost efficiency: Over time, these systems lower operational and maintenance costs.

- Safety improvement: Robots equipped with vision can perform dangerous tasks in hazardous conditions.

Driving Innovation and Competitiveness

Businesses implementing these systems gain a competitive edge through higher accuracy, faster turnaround, and improved customer satisfaction. By allowing machines to make data-driven visual assessments, companies achieve superior results in production, logistics, and research environments.

Challenges and Limitations

Technical and Operational Barriers

Despite their promise, implementing robotic vision comes with challenges:

- Complex programming and calibration: Integrating multiple sensors and AI models requires advanced expertise.

- High initial investment: Quality cameras, sensors, and computing systems can be costly.

- Data management issues: Storing and processing visual data in real time demands significant computational power.

- Environmental sensitivity: Lighting, motion blur, and dust can affect image accuracy.

Ethical and Workforce Considerations

As intelligent machines become more capable, concerns about job displacement and ethical data use arise. However, experts emphasize that these systems are designed to assist rather than replace humans. The goal is collaboration enabling humans to focus on creative and analytical tasks while machines handle repetitive, precision-based operations.

Real-World Examples

Manufacturing Excellence

In the automotive industry, robots equipped with advanced vision systems handle welding, assembly, and quality inspection with unmatched precision. For instance, car manufacturers use 3D vision to ensure perfect alignment of components during assembly.

Healthcare Innovations

Medical robots use visual sensors to perform surgeries with minimal incisions, improving recovery times and reducing human error. Vision-guided robotic arms assist surgeons during complex procedures, ensuring accuracy down to the millimeter.

Smart Warehousing

In logistics, vision-guided drones and robots identify, pick, and sort items in massive warehouses. Companies like Amazon and Alibaba use intelligent vision to track inventory, improving order fulfillment speed and accuracy.

Future Outlook

The Path Ahead for Intelligent Robotics

The future of robotic vision is moving toward full autonomy, where machines can make complex decisions without human guidance. With advancements in AI, edge computing, and sensor fusion, robots will achieve near-human perception.

Integration with Emerging Technologies

Future systems will integrate with technologies like augmented reality, the Internet of Things (IoT), and quantum computing. This convergence will amplify precision, allowing robots to operate seamlessly in dynamic environments.

A Vision-Driven Future

As industries evolve, robotic vision will continue to redefine machine intelligence making automation smarter, faster, and more responsive. The journey ahead promises a world where intelligent machines not only see but truly understand and interact with their surroundings.

Conclusion

Robotic Vision Systems are transforming the boundaries of automation by giving machines the power to see, learn, and make intelligent decisions. From manufacturing and healthcare to logistics, their influence is reshaping how industries operate with precision and efficiency. As technology continues to evolve, these systems will play a key role in achieving smarter, safer, and more adaptive automation. To stay ahead in this rapidly advancing field, explore emerging innovations in machine intelligence and discover how visual automation is shaping the future of intelligent robotics.

Pingback: Robotic Vision Systems: Transforming Industrial Automation Through Intelligent Perception - Techyways